Original Source: Fast.Co Design, May 18, 2016

Cities are shaped by fire. From Chicago to San Francisco, enormous swathes of urban fabric were wiped away by accident in the 19th century. These horrific disasters did more than just clear the way for new development, though. They also helped spur building codes that outlawed the use of one particularly dangerous building material: timber.

More than a century later, a massive reversal is taking place. An 80-story timber skyscraper is being proposed by British architects. Architects in the U.S. are racing to clinch the title of the tallest wood building in the country. Elsewhere in the world, architecture students are enrolling in programs focused solely on timber construction technology. The federal government is now funneling money into promoting timber in tall urban buildings.

Fueled by the wood products industry (a $200 billion market, if you include paper), sustainability issues, and emerging ideas from building science, wood buildings are no longer pastoral artifacts. According to many scientists and architects—and not a few wood lobbyists—they’re the future. But not everyone agrees.

THE ARCHITECTURE

Even if you don’t live in Minneapolis, it’s easy to follow the progress at 316 Third Avenue North, a construction site three blocks from the banks of the Mississippi River. You can watch work progress through an always-on work-zone camera, or check out drone footage, or even see the view from a GoPro mounted to a structural panel as it’s hoisted into place.

There’s a good reason for this careful documentation. This is the site of T3, a project to build the first “mass timber” building in the United States, as MinnPostreported this year. T3 is a litmus test for whether a building technology that’s seen adoption in Scandinavia, Central Europe, and Japan can find a market in the U.S.

“The current challenge is a chicken and egg situation,” writes Michael Green, the British Columbia-based architect behind the project and the outspoken advocate for wood architecture, over email. “It is hard to educate people in new timber technology quickly when there are so few experts to turn to.” Green, whose TED Talk about timber skyscrapers has been viewed more than a million times (no small feat for a lecture on architecture), has become an expert on timber buildings—and the fraught process of getting them past outdated building codes in the U.S.

The 19th century was the age of steel, the 20th of concrete. This century is the new age of timber.

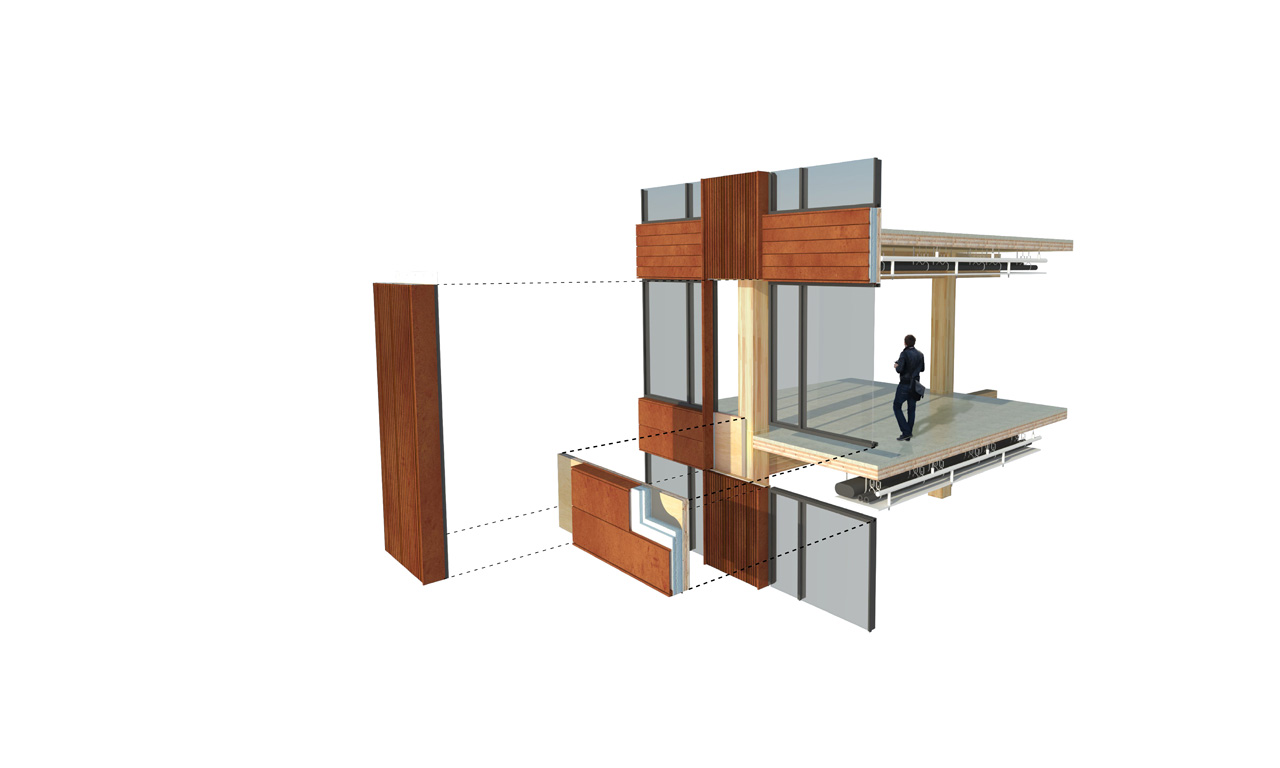

When it’s finished this year, T3 will offer high-end office space with a great backstory: Its seven stories are supported by massive timber beams and panels very much unlike anything you’ll find at a weekend cottage. The structural members are created by laminating pieces of wood together, using either glue or nails, to create massive timber beams that are stronger than steel by weight—a genre of building technologies known as “cross-laminated timber,” or CLT. T3 will have 11-foot ceilings and massive glass windows thanks to the incredible strength of these solid timber panels.

Other mass timber projects designed by SHop Architects (in New York) and LEVER Architecture (in Portland), the two winners of last year’s U.S. Tall Wood Building Prize Competition, are also forthcoming. Alongside T3, these projects will be valuable demonstrations for an industry that can be slow to adapt. Green wants to share what he’s learned, first through a new online education course run through Design Build Research, his nonprofit design education program. “Far more private and public sector clients are talking about wood than even I could have imagined,” he says. “Some days I almost feel like we are moving from early adopters to mainstream already.”

It’s unusual to hear an architect talk with such immediacy and passion about a building technology. But to advocates of mass timber, it’s the solution to a problem that is planetary in scale. It’s not just a technology—it’s a world-saver.

THE SCIENCE

That idea has plenty of proponents and critics alike. CLT emerged in the 1990s in Switzerland, when researchers invented the process of strengthening less-than-perfect wood by layering in slats of alternating direction. By reversing the grain direction on each layer of wood, they created a much stronger product. It’s also surprisingly resistant to the fires that made it a hated building material in the 19th century. Because CLT beams and panels are so thick, exposing them to flames creates a layer of “char,” or ash, that insulates the structurally stable interior for up to three hours, according to tests by Canada’s National Research Council.

Still, CLT could’ve easily remained an obscure niche material. But around the same time, climate change was becoming a major topic on the global stage. The construction industry alone produces as much as 39% of CO2 emissions in the U.S., according to the Green Building Council, thanks to the production of cement and steel, not to mention their transport. Timber, by comparison, is what’s called a “carbon sink,” or a material that absorbs more carbon than it produces (and thus reduces the amount of emissions in the atmosphere). In that light, using more timber—and less steel and concrete—seems like a no-brainer.

But sequestering carbon is complicated. Living forests are already excellent carbon sinks. Half of a tree’s weight is just sequestered carbon, according to the Forestry Service. Some scientists argue that leaving forests alone is a better way to store carbon than farming them to replace steel and concrete. “Keeping the trees in the forest is far more valuable for carbon storage alone—than any value derived from logging,” says Mike Garrity, the Montana-based executive director of Alliance for the Wild Rockies, a nonprofit dedicated to protecting the natural ecology of the region. Garrity argues that the timber industry is pushing assumptions about the sustainability of timber that haven’t been proven by science.

Others point out that the natural life and death of forests needs to be considered. As trees rot and fall, they release their stored carbon and contribute to emissions, too. By that logic, responsible logging of mature trees would keep a forest healthy and replace CO2-hogging building materials.

In short, it’s an incredibly complex problem to study scientifically. And since this is a problem that’s only been studied for a few decades, the data just isn’t there. “Today’s forest management is more of a gamble than a scientific debate,” wrote two ecological scientists in Nature in 2014. “The future of the world’s forest should not depend on tossing a coin.”

THE POLITICS

Earlier this month, a group of bipartisan senators introduced a bill called theTimber Innovation Act, which would create an R&D program funded by the federal government and managed by the U.S. Department of Agriculture’s Forest Products Laboratory.

Its goals would be myriad: better understand the “environmental life cycle” of timber building products, increase the safety of tall timber buildings, and advocate for updated building codes that include easements for timber. The bill is supported by dozens of lumber trade groups, which could complicate its goals and the objectivity of its research. Even Green has accepted research grants and paid speaking engagements from the timber industry, though he comments that he and his organization “do not speak for forestry companies or the industry” and has declined to endorse organizations like the Sustainable Forest Initiative in the interest of remaining independent.

The one thing everyone agrees on? We need more data. “Additional funding to support this research is needed to advance our knowledge and enable us to make informed decisions,” writes Architect Kate Simonen, who directs the research-focused Carbon Leadership Forum.

The climate is rapidly changing, and the way trees store carbon right now may change as that transformation accelerates, along with the way building materials are made and consumed. It’s going to take years to understand that process.

Many developers are catching on to the idea regardless. Albina Yards, a four-story CLT office building designed by Lever Architecture in Portland, will be the first building in the country to be built with CLT produced in the United States when it’s finished this year. In a project statement, the architects at Lever argue that increasing demand for timber products will boost responsible forestry practices that increase carbon sequestration:

“Countless studies show that the most important factor in maintaining forests as forests is to ensure that landowners can realize a suitable return on their investment in forestland. Without that incentive, private landowners would be inclined to convert their land to other uses, thereby reducing the total amount of forestland. For this reason, increased demand for wood products actually has a positive impact on maintaining forest resources.”

Meanwhile, architects at the University of Cambridge presented new research last month that proposes how much taller buildings—true skyscrapers, like a 1,000-foot-tall version in London—could be built with heavy timber structures. As of this week, Architectural Association now offers a master of science course focused on robotic construction with wood.

Back in the U.S., T3 is nearing completion, with windows and insulation visible in the livestream. “Systemic change is fascinating,” Green writes. Within the last three years alone, he says the shift within the building industry has been dramatic. “Information exchange is happening quicker than imagined, and more people want to come on board every day. That energy cannot be stopped.”

It will take decades before scientists can truly understand the relationship between CO2, forests, and wood buildings. But as more architects use the technology, it may begin to shape our cities long before that day arrives.