T3, our LEED Gold Certified mass timber office building in Minneapolis, was a game-changer for the commercial building industry and a milestone for mass timber construction in the United States. It was the first modern timber building to be built in the United States in more than 100 years, and at the time of completion (September 2016), the largest in North America.

Details

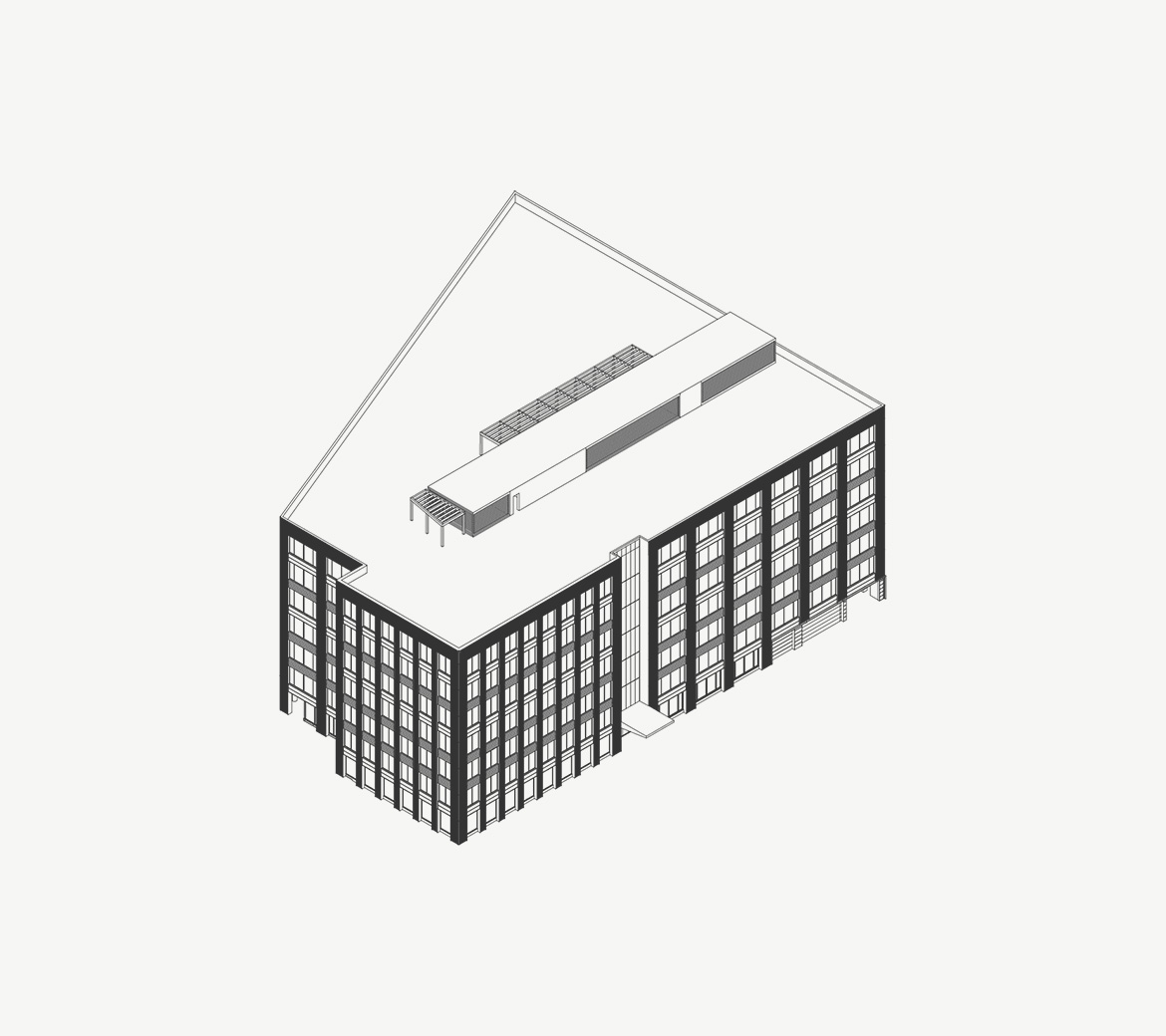

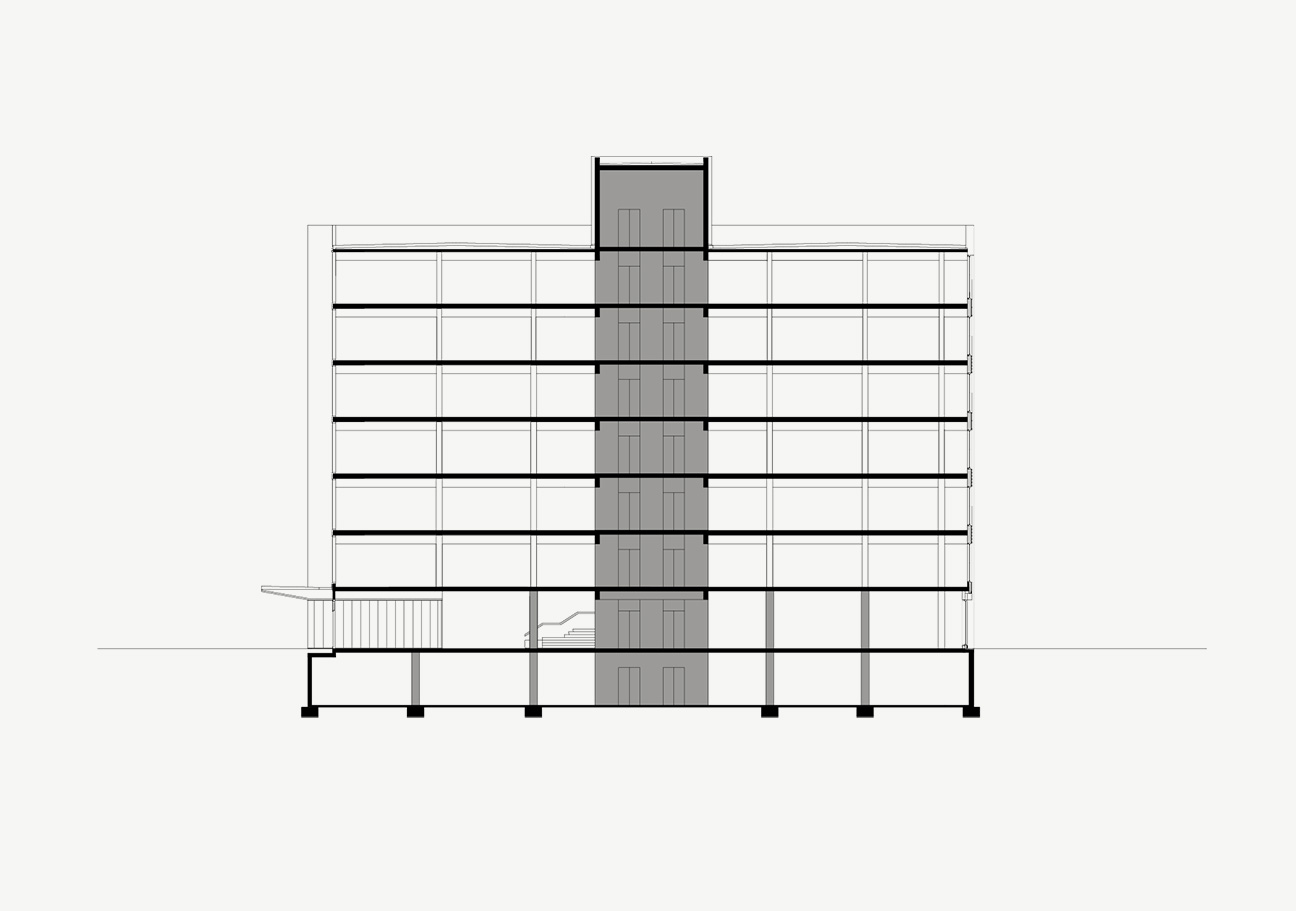

We have designed T3 to build on the character of the past with a progressive modern perspective. The seven-storey, 220,000 sq. ft. commercial building offers a mix of retail and office space, integrating into existing transit networks and the historic fabric of the city.

The design marries traditional, industrial proportions with modern materials and detailing. T3 is respectful of its neighborhood and responds to its context with a simple massing. The form and exterior articulation create a quiet building – responding to and complementing the historical buildings rather than drawing attention to it.

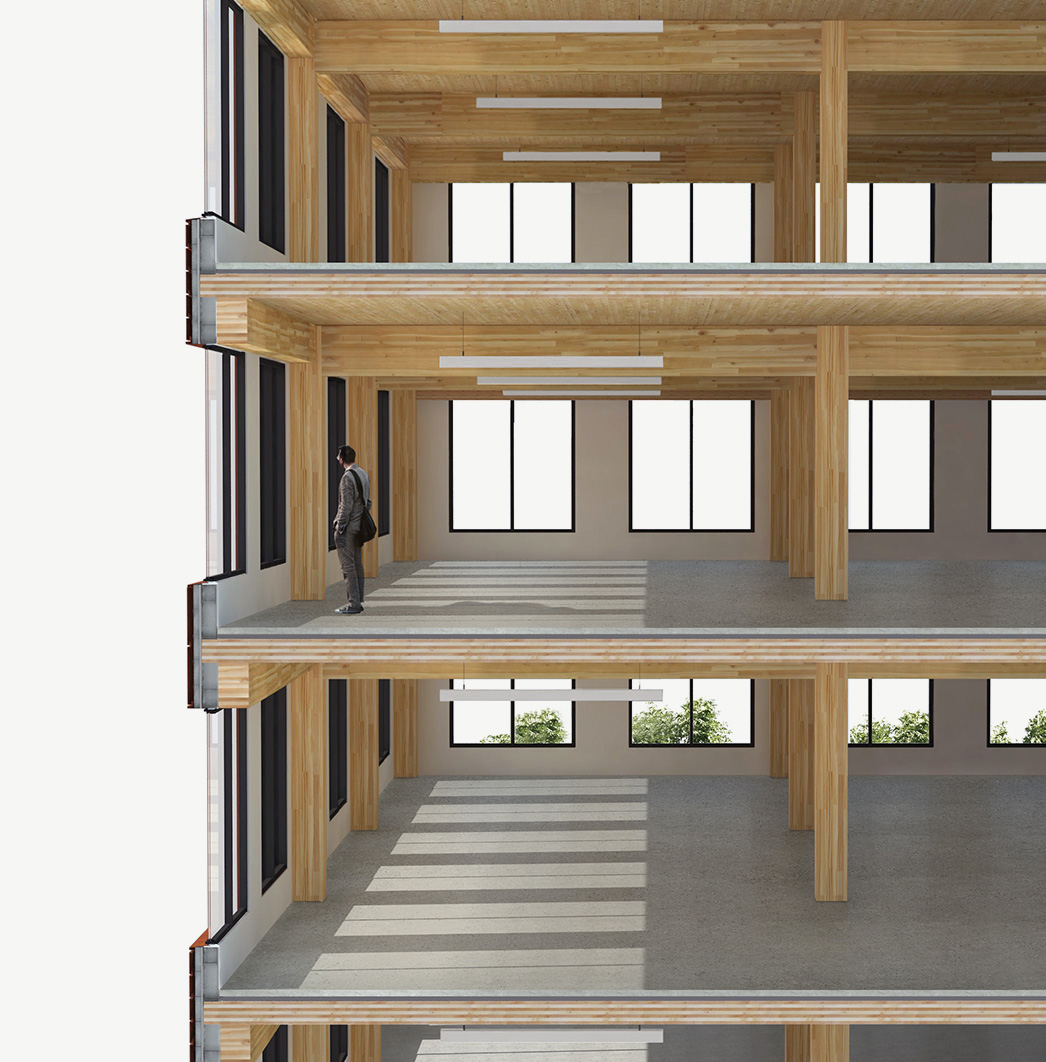

Inside the building, exposed mass timber columns and floor slabs recall the heavy timber construction of the building’s predecessors. While the historic brick-and-timber structures of the district used old growth solid timbers for columns, beams, and even floor joists, T3’s modern technological approach uses engineered wood components (chiefly glulam and nail laminated timber). These modern materials bring the warmth and beauty of wood to the interior and promote a healthy indoor environment for occupants.

Quote

“ Yet T3 is an important building – not because it is technically exceptional, but because it suggests a new normal in architecture…This is the building that marks the acceptance of 21st-century engineered “mass timber” by the North American development industry, an advance that could see wood – a lightweight, strong, sustainable alternative – begin to take the place of concrete and steel as a structural system in midrise and high-rise buildings.”

Process

Uniquely, the timber structure of the building itself is a great part of the sustainability and carbon footprint story of this building. Using the Canadian Wood Council’s carbon calculator, one can study the carbon impact of different building materials and approaches from a life cycle perspective. Our data from past mid-rise timber projects has shown a significant reduction in life cycle impact for a timber structure, as compared to a concrete structure. The timber structure is less energy-intensive to extract and is renewable with minimal inputs. It requires relatively little energy input to process raw logs into engineered wood products for building (whereas concrete and steel require significant material and energy inputs). Finally, the carbon that is absorbed by trees through the photosynthesis process is actually sequestered in the wood fiber throughout its lifetime in the building. The project will effectively be a carbon sink for its lifetime, and for as long as the wood products can be recycled and reused.

- Approximately 3,600 cubic metres of wood are used in the structure, which will sequester about 3,200 tonnes of carbon for the life of the building.

- Timber was erected at a speed exceeding conventional steel-framed or concrete buildings – completed in just 2.5 months at an average of 9 days per floor.

- Over 1100 8’x20’ NLT (Nail Laminated Timber) panels are used in the project – the equivalent square footage of nine hockey rinks.

- The majority of NLT was made of lumber from trees killed by the mountain pine beetle.

Links & Resources

Recognition

NAIOP Minnesota – Award of Excellence, 2017

–

AIA Chicago – Distinguished Buildings Award, 2017

–

Azure AZ Awards – Environmental Leadership + People’s Choice, 2017

–

US Woodworks Wood Design – Special Achievement Award, 2017

–

WoodWorks Wood Design Award BC – International Wood Design, 2017

–

Wood Design & Building – Citation Award, 2016

–